The Thermoforming Process: How We Create Tactile Signs

Thermoformed signs are not new to the industry, in fact, thermoforming is an industry-leading technology and is the best way to create tactile signs for exterior and interior signage projects. The process differs when compared to creating photopolymer signs, and the result is a highly customizable sign that looks amazing and lasts a lifetime.

At Encompass Sign Systems, our thermoforming process allows us to create ADA signs that meet all the needs of building owners, the specifications of designers and all applicable ADA sign regulations.

Start with the Design

The thermoforming process all begins with a great sign design. You can easily access our 101400 Studio, and in just three easy steps you will have a list of project-tailored specifications in just minutes.

Using the 101400 studio, you can:

- Choose a design family from our pre-built catalog

- Tailor sign types and colors to match their specific project

- Download free specifications and design drawings

From there, our team can get to work manufacturing your tactile signs.

Our Thermoforming Process

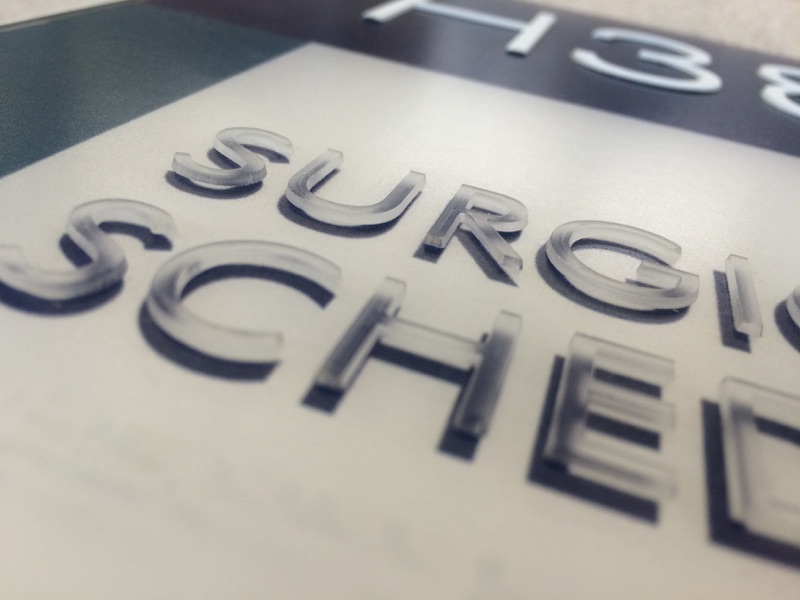

The thermoforming process creates a vibrant, durable sign that can be used in interior and exterior settings. The process involves heating a single sheet of acrylic and pressing it to fill your customized mold, allowing for the creation of any desired shape.

Unlike photopolymer signs, which are created using harmful chemicals like polymer resins and film negatives, thermoformed signs allow for more customization during the production process without harmful chemical waste. A few of the many customization options that you can take advantage of include

- Shaping, sizing and depth (using layered acrylics)

- Color and graphic integration

- Sign textures and edges

- 3D shaping

Any of these design aspects can be combined to create a sign that is unique to your client’s business or organization.

Learn More or Get Started Today

To see examples of tactile signs that were created using our revolutionary thermoforming process, take a look at the gallery page on our website. If you want to get started on designing a sign today, try our 101400 studio or contact our team.